- Data Sheet: C1-15

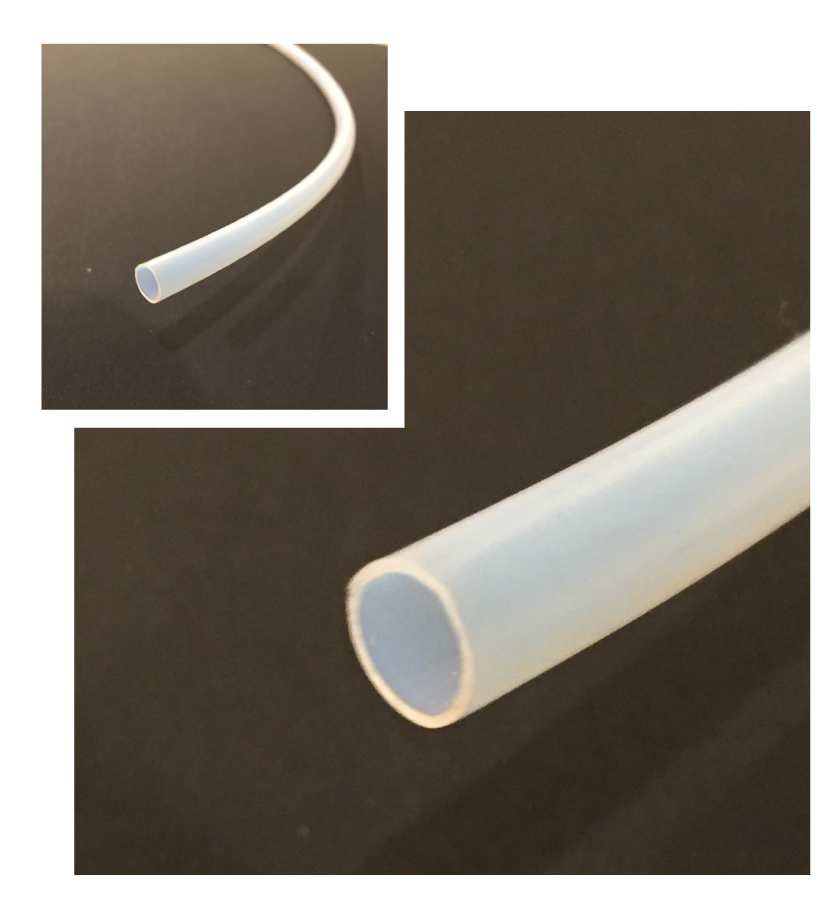

θ THETA - PTFE LAB / PTFE Thin Wall Tubes

θ THETA - PTFE LAB / PTFE Thin Wall Tubes

|

Technical specifications Industrial sectors Upon request DIFLON can produce TWT with custom specifications such as: |

| Effect of temperature on pressure resistance | |

|---|---|

| T(°C) | P(%) |

| 23° | 100 |

| 50° | 85 |

| 100° | 65 |

| 150° | 50 |

| 200° | 35 |

| ID mm |

OD mm |

Weight (Kg/m) |

Burst pressure (MPa a 23°C) |

Radius of curvature (mm) |

|---|---|---|---|---|

| 1,5 | 3,2 | 0,012 | 110 | 12,0 |

| 1,5 | 3,5 | 0,017 | 125 | 12,0 |

| 2,0 | 3,0 | 0,009 | 70 | 18,0 |

| 2,0 | 4,0 | 0,020 | 110 | 16,0 |

| 2,5 | 3,5 | 0,010 | 55 | 25,0 |

| 2,5 | 4,0 | 0,017 | 80 | 18,0 |

| 2,5 | 5,0 | 0,032 | 110 | 20,0 |

| 3,0 | 4,0 | 0,012 | 50 | 32,0 |

| 3,0 | 5,0 | 0,027 | 85 | 25,0 |

| 3,0 | 6,0 | 0,046 | 110 | 24,0 |

| 4,0 | 5,0 | 0,015 | 40 | 50,0 |

| 4,0 | 6,0 | 0,034 | 70 | 36,0 |

| 4,0 | 7,0 | 0,056 | 90 | 33,0 |

| 4,0 | 8,0 | 0,081 | 110 | 32,0 |

| 4,5 | 6,5 | 0,037 | 60 | 41,0 |

| 5,0 | 6,0 | 0,018 | 30 | 50,0 |

| 5,0 | 7,0 | 0,041 | 60 | 49,0 |

| 5,0 | 8,0 | 0,066 | 80 | 43,0 |

| 5,0 | 9,0 | 0,055 | 95 | 41,0 |

| 6,0 | 7,0 | 0,022 | 25 | 98,0 |

| 6,0 | 8,0 | 0,048 | 50 | 64,0 |

| 6,0 | 9,0 | 0,076 | 70 | 54,0 |

| 6,0 | 10,0 | 0,109 | 85 | 50,0 |

| 6,5 | 9,5 | 0,081 | 65 | 60,0 |

| 7,0 | 9,0 | 0,054 | 40 | 81,0 |

| 7,0 | 10,0 | 0,087 | 60 | 67,0 |

| 7,5 | 9,5 | 0,058 | 40 | 90,0 |

| 8,0 | 9,0 | 0,029 | 20 | 162,0 |

| 8,0 | 10,0 | 0,061 | 40 | 100,0 |

| 8,0 | 12,0 | 0,136 | 70 | 72,0 |

| 9,0 | 10,0 | 0,032 | 15 | 205,0 |

| 9,0 | 11,0 | 0,068 | 35 | 120,0 |

| 9,0 | 12,0 | 0,107 | 50 | 85,0 |

| 10,0 | 11,0 | 0,036 | 15 | 242,0 |

| 10,0 | 12,0 | 0,075 | 30 | 144,0 |

| 10,0 | 13,0 | 0,116 | 45 | 113,0 |

| 10,0 | 14,0 | 0,162 | 55 | 98,0 |

| 11,0 | 13,0 | 0,081 | 30 | 145,0 |

| 12,0 | 14,0 | 0,878 | 25 | 196,0 |

| 13,0 | 15,0 | 0,095 | 25 | 225,0 |

| 14,0 | 16,0 | 0,101 | 20 | 256,0 |

| 15,0 | 17,0 | 0,108 | 20 | 289,0 |

| 15,0 | 18,0 | 0,167 | 30 | 216,0 |

| 16,0 | 18,0 | 0,115 | 20 | 324,0 |

| 16,5 | 19,5 | 0,182 | 30 | 254,0 |

| 17,0 | 20,0 | 0,187 | 25 | 267,0 |

| 18,0 | 20,0 | 0,128 | 15 | 400,0 |

| 18,0 | 22,0 | 0,270 | 30 | 242,0 |

| 19,0 | 22,0 | 0,208 | 20 | 323,0 |

| 20,0 | 22,0 | 0,142 | 15 | 325,0 |

| 20,0 | 24,0 | 0,297 | 25 | 288,0 |

| 21,0 | 24,0 | 0,228 | 20 | 384,0 |

| 22,0 | 24,0 | 0,155 | 15 | 576,0 |

| 24,0 | 27,0 | 0,258 | 20 | 486,0 |

| 24,5 | 27,0 | 0,217 | 15 | 583,0 |

| 25,0 | 28,0 | 0,268 | 15 | 523,0 |

| Diameter (mm) |

Tolerance (mm) |

|---|---|

| 1,5 < d ≤ 5 | ± 0,10 |

| 5,1 < d ≤ 7 | ± 0,15 |

| 7,1 < d ≤ 10 | ± 0,20 |

| 10,1 < d ≤ 15 | ± 0,30 |

| 15,1 < d ≤ 20 | ± 0,40 |

| 20,1 < d ≤ 30 | ± 0,60 |

| Wall thickness (mm) |

Maximum excentration tolerance (mm) |

|---|---|

| 0,5 | 0,1 |

| 1 | 0,15 |

| 1,5 | 0,17 |

| 2 | 0,2 |

| 2,5 | 0,25 |

| 3 | 0,3 |

| Technical specifications | Unit of measure | Test methods (ASTM) | PTFE | PFA |

|---|---|---|---|---|

| Physical | ||||

| Specific gravity | gr/cm3 | D792 | 2,16 | 2,15 |

| Appearance | Transluced White | Transparent | ||

| Water permeability | % | D570 | <0,01 | <0,03 |

| Mechanical | ||||

| Tensile Strength | Kgf/cm2 | D638 D1708 |

250-300 | 280 |

| Elongation at break | % | D638 | 250-400 | 300 |

| Modulus of elasticity | MPa | D747 | 440 a520 | 650 |

| Hardness | Shore D | D2240 | 55-65 | 60-65 |

| Thermal | ||||

| Melting point | °C | +327° | +310° | |

| Maximum operating temperature | °C | +260° | +260° | |

| Minimum operating temperature | °C | -60° | -60° | |

| Electrical | ||||

| Dielectric strength | KV/mm | D149 | 80 | 80 |

| Dissipation factor | 0,0003 | 0,00075 | ||

| Chemical | ||||

| Chemical resistance | Excellent | Excellent | ||

| Endurance to atmospheric pitting corrosion | Excellent | Excellent | ||