Crimping

Crimping Example

Crimping

Diflon Lined hoses are high quality products. They are reliable and they have a long life. In order to obtain the best performances, it is important to choice the correct type and install them in right manner. Diflon Flexiline hoses can be used in several fields. In case of particularly critical conditions, please contact our technical service. In normal conditions please apply the following instructions. The sketches show proper application and installation compared to faulty procedures.

Cleaning

Guideline for cleaning and sanitizing holes

Consigli per la Pulizia

The cleaning and sanitizing advices here below indicated must be considered guidelines only. It is necessary that all applicable government regulations pertaining to the cleaning and sanitizing of the food hoses and food hoses assemblies be followed and respected. Therefore we declare that governmental regulations supersede the guideline contained herein. The hoses’ life is directly connected to the cleaning and sanitizing process due to the mechanical and chemical stresses which occur during the process itself. The service period of rubber hoses is dependent on their formulation and the environment of use which in turn is influenced by the product, process temperature, cleaning and bactericidal compounds and time of exposure. Users should frequently check the condition of the rubber hose material product contact surfaces. Such observations are necessary to determinate the actual sanitary service period of rubber hoses. It is further recommended to replace the rubber hose before surface imperfections or sloughing occurs. A planned periodic replacement should be established and followed. Food hose users should be guided by the cleaning and sanitizing procedures of their own specific production field. For example the wine industry may have different standards than the dairy industry and any standards applicable to a specific industry supersede the guideline below indicated. The cleaning and sanitizing of food hoses and hose assemblies is intended to remove any food particles or residues such as detergents or disinfectant that could be the source of harmful bacteria microorganism or other sources of contamination. The effectiveness of the guidelines below indicated depends on the attention and assiduity given by users.

Frequency

The frequency of the cleaning and sanitizing cycle needs to be programmed in according to the type of food or beverage used and to the contamination risk level. In principle, the cleaning and sanitizing process should be conducted on a frequent basis.

Washing

An accurately washing with hot drinking water is the first step in the cleaning process. Hot potable water will facilitate the cleaning, but not eliminating the need nor to clean the pipe with suitable detergents, nor to disinfect it. The temperature of the hot water and duration of the washing/rinsing cycle will depend upon the characteristic of the material. The initial washing/rinsing with hot potable water should finish as soon as the conveyance process will be completed. All residual water and any other residue from the initial washing/rinsing cycle must be drained away completely.

Cleaning / Disinfecting

The selection of a specific detergent and of a specific disinfectant will depend on the material/products being conveyed. The recommendation of the manufacturer of the detergent and of the disinfectant should be strictly followed especially regarding concentration levels. After the cleaning of the hose with detergent followed by the rinse of it with potable water, the hose must be sterilized either with steam or withchemical solution. Steam is classified as “Physical” disinfectants: its effectiveness in eliminating bacteria and other contaminants varies according to the material and to the procedure employed by the users. Chemical disinfectant such as caustic soda, nitric acid, phosphoric acid, chloroacetic acid or other acids suitable for disinfecting food hoses must be carefully selected to ensure optimal effectiveness while also assuring maximum safety and health. When selecting a particular disinfectant it is necessary to pay strict attention to concentration levels, temperature, cycle time, etc. The type of product/material being conveyed must be taken into consideration when selecting a specific disinfectant. As soon as the disinfecting treatment with chemical solutions is made, the hose must be carefully rinsed for a sufficiently long time with potable water in order to eliminate any chemical residues from the disinfecting treatment.

Process Controls

The result of the cleaning and sanitizing process must be regularly checked to ensure that all contamination and residuals have been eliminated. Any non conforming events need to be solved with a corrective action procedure. The hoses’ life is directly connected to the cleaning and sanitizing process due to the mechanical and chemical stresses which occur during the process itself. The service life of rubber hoses is directly dependent on frequency and time of exposure to PHYSICAL and CHEMICAL disinfectants. Users should frequently check the condition of the rubber hose material product contact surfaces. Such oBServations are necessary to determinate the actual sanitary service period of rubber hoses. The present advices are based on tests and on generally available sources, that are believed to be reliable. However must be considered as indicatives cause they don’t take care about all variable that may arise during the utilization.

Installation

Installazione instruction for hoses

Installazion

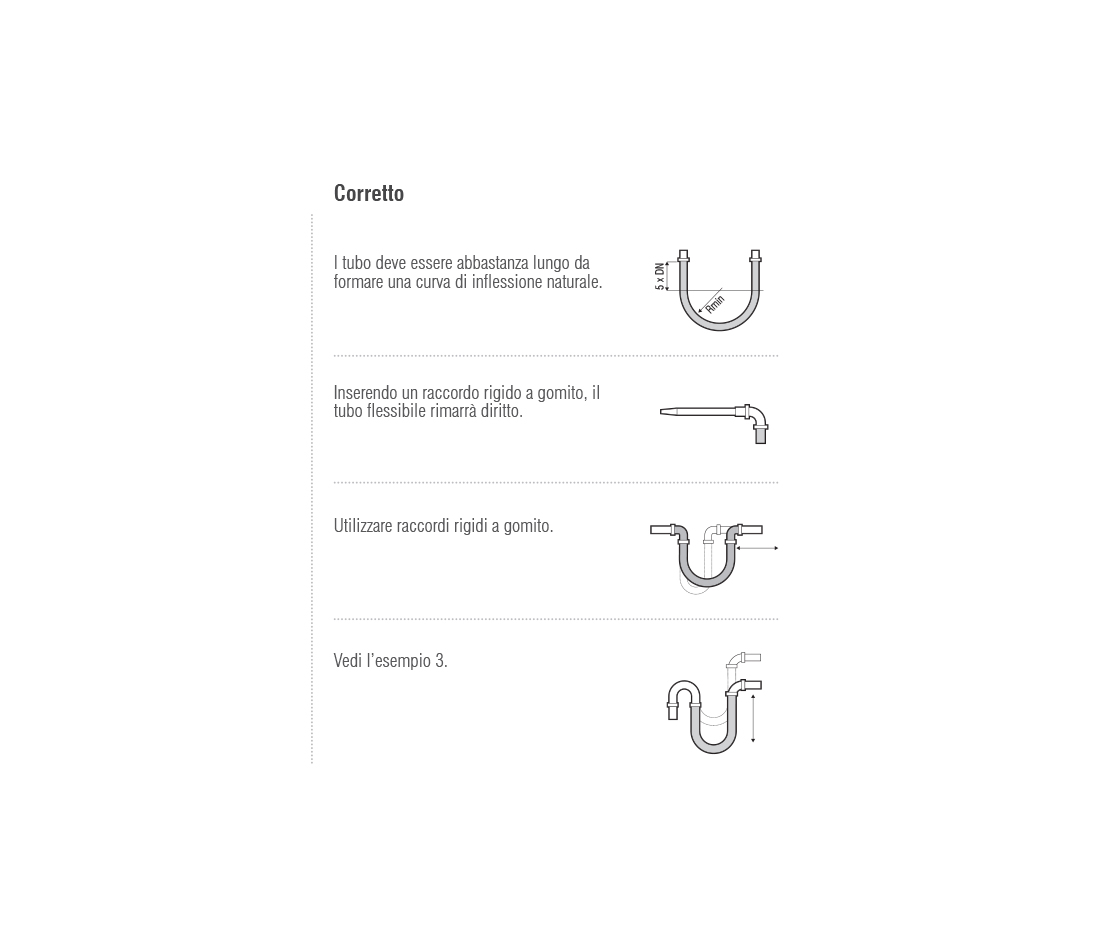

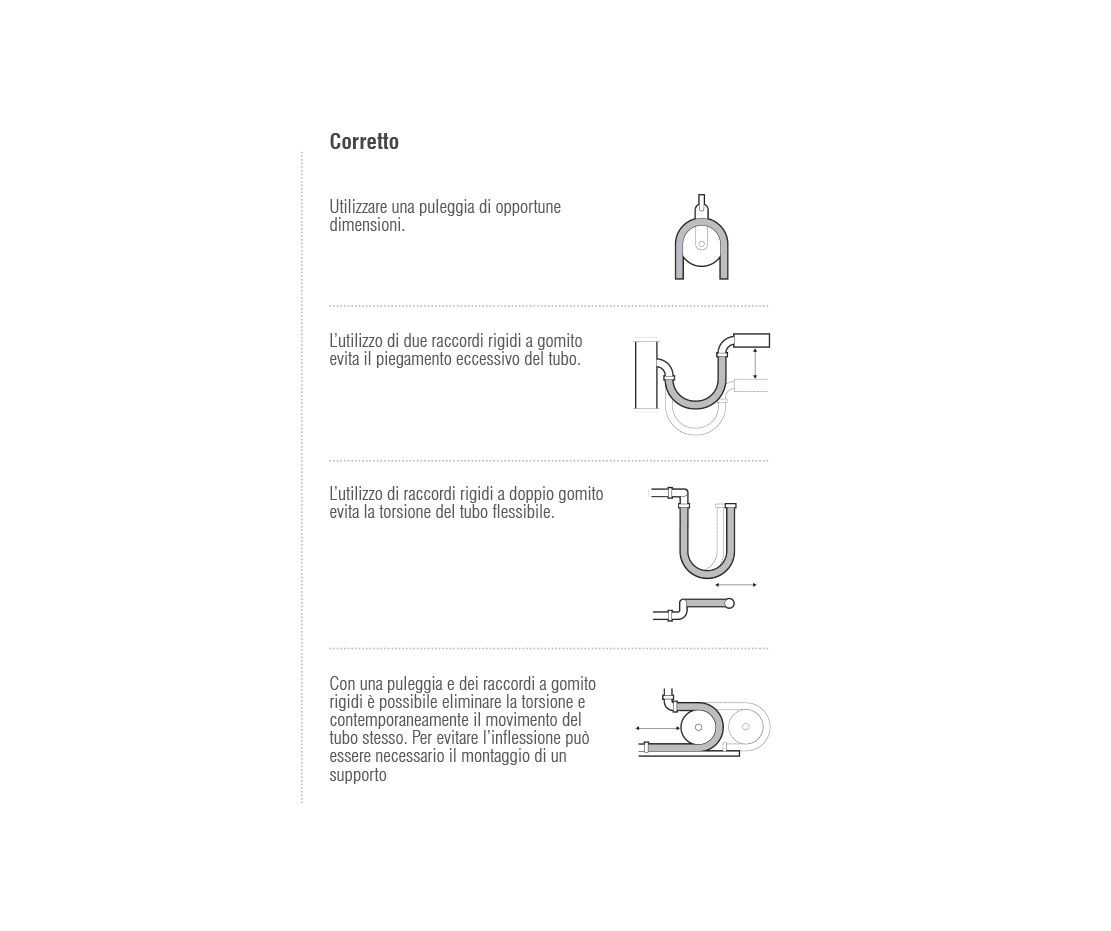

Diflon Lined hoses are high quality products. They are reliable and they have a long life. In order to obtain the best performances, it is important to choice the correct type and install them in right manner. Diflon Flexiline hoses can be used in several fields. In case of particularly critical conditions, please contact our technical service. In normal conditions please apply the following instructions. The sketches show proper application and installation compared to faulty procedures.

Correct choice of length:

The ends of the hose should not be bended or twisted. This so-called neutral portion of the hose ends should have a length of 5 x DN. Bending radius should not be less than wath indicated in our catalogue. S-bends are to be avoided. Avoid any hose twist. In most cases hose twist can be avoided by adopting opportune solutions during installation. For example, if the hose moves, it should be installed so that the axis of the hose and the direction of the motion are on the same plane. In this case hose twist cannot occur. Ensure strain-free tightening. Use a second wrench on hose socket to prevent strain during final tightening.