Flat Gaskets

Flat Gaskets

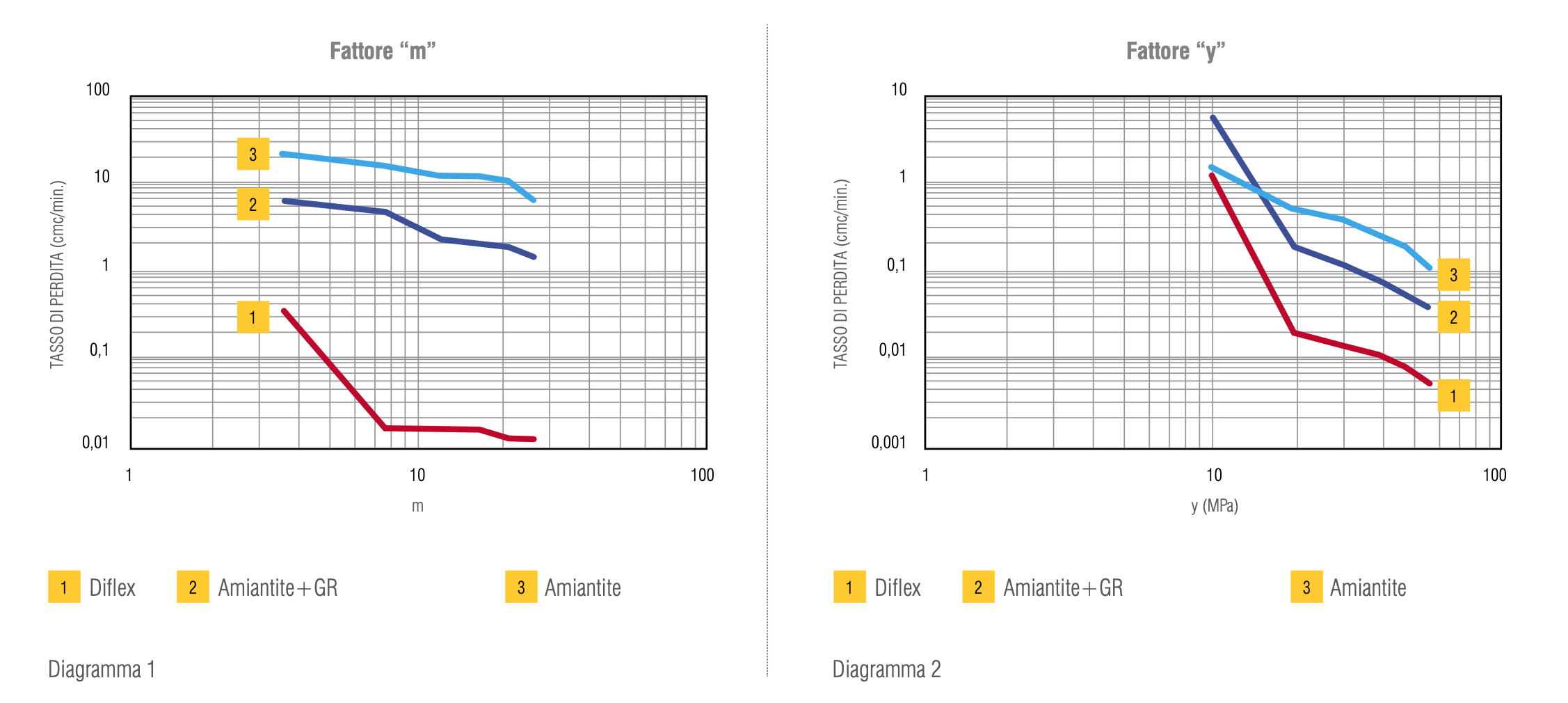

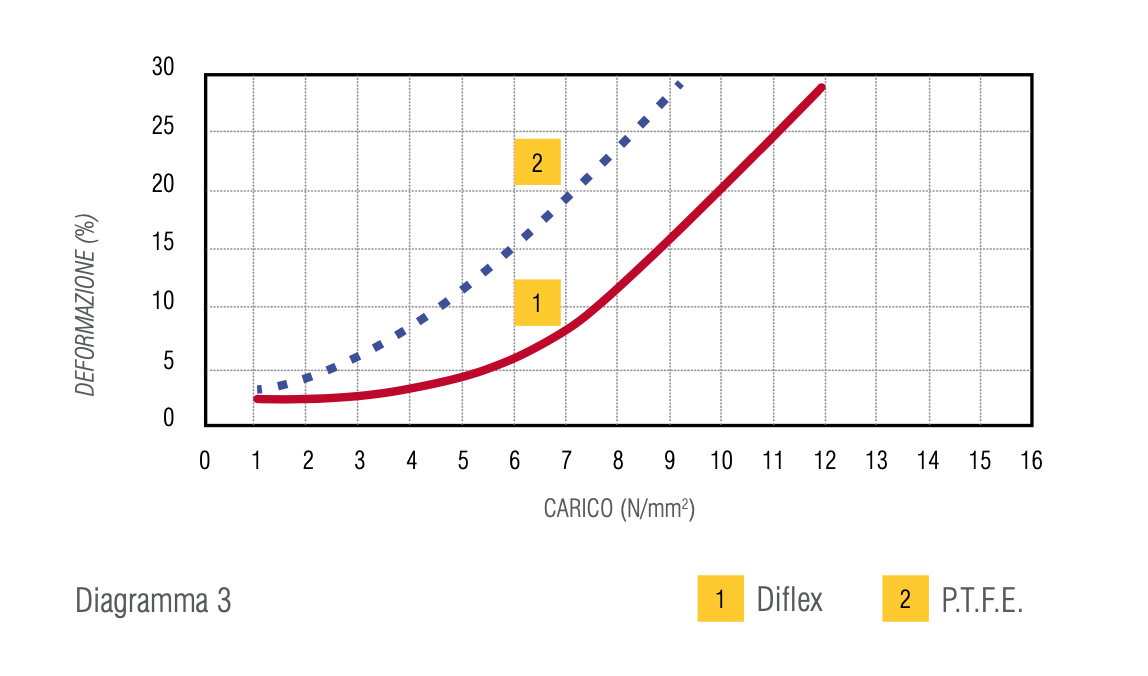

Y and M Factors

For environmental protection and health protection reasons, gaskets containing asbestos must be replaced in industries. A valid alternative is represented by universal DIFLEX gaskets. Research and experiments by the DIFLON company have shown that the y and m values of the amiantite gaskets are absolutely compatible with the same values of the DIFLEX gasket, therefore by replacing them during operation, the tightening calculations do not vary; The engineering and maintenance functions in the factories are thus simplified. (Documentation available at the DIFLON technical office). See graphs 1 and 2.

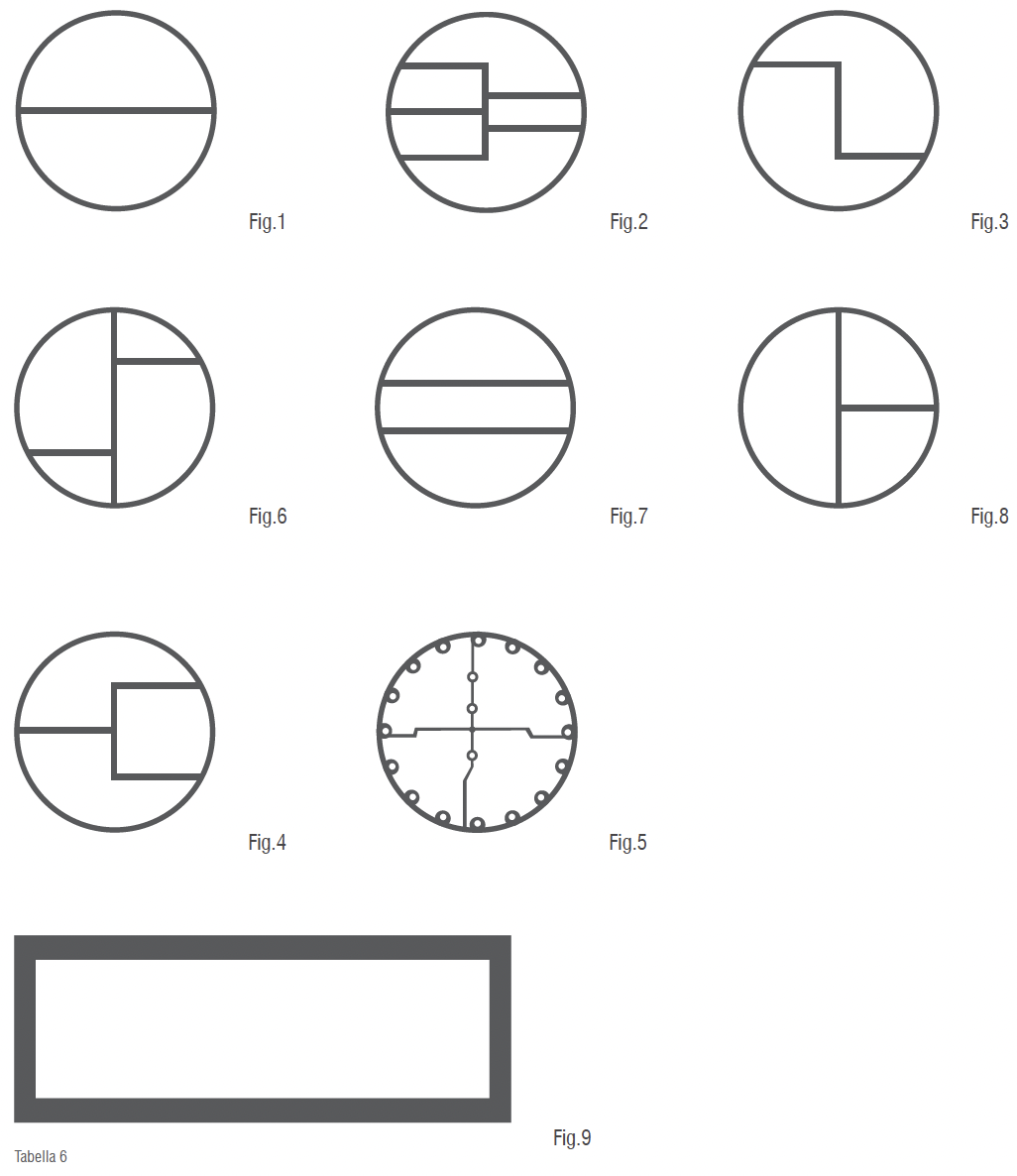

Application Examples

• flat gaskets for flanges of any type, with or without grooves

• profiled flat gaskets, with chamber, for rapid assembly, for exchangers and pressure equipment.

Our exclusive welding technology allows us to provide gaskets with no limits in terms of diameter and shape.

Purity of product for diflex gaskets

DIFLEX can be used, without contra-indications, in the production of basic commodities, since the monomers used for its manufacturing fully comply with EEC 90/128-93/9-92/39 regulations and with title 21, sub-section 177/1550 “Perfluorocarbon resin” of Food and Drug Administration, U.S.A.

Fire resistance of DIFLEX Gaskets

DIFLEX is a barely inflammable material, it has a LOI value of 95, and only burns in atmospheres with an oxygen content of more than 95%. The tests carried out by DIFLON, with the flame directly oriented onto the DIFLEX gasket, gave very good results, even though the material is a polymer.DIFLEX gaskets were adopted for the first time in 1993 by large complexes and since then they have been included among the specifications drawn up by major engineering companies. Field experience shows that DIFLEX gaskets can be used for continuous service at a temperature range of -150°C to +260°C and also under high pressure.

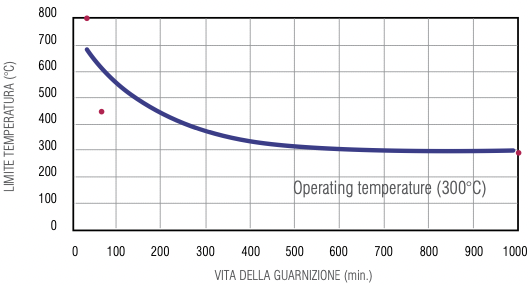

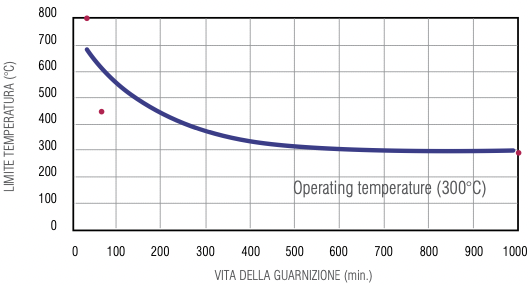

Maximum operating temperature and gasket life at 50 bar

| Temperature °C |

Min. Duration of the seal. |

| 800 |

33 |

| 450 |

65 |

| 240 |

illimitato |

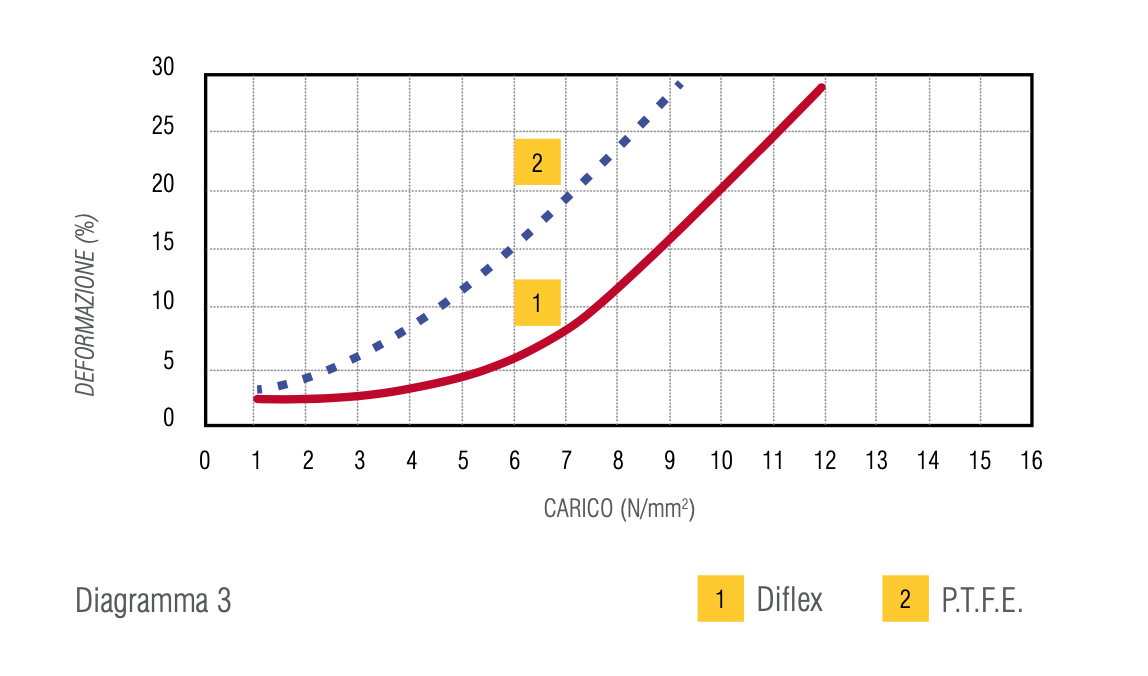

Strain (%) at 150°C after 100 hours

Diflex Gaskets in Operation

DIFLEX gaskets were adopted for the first time in 1993 by large complexes and since then they have been included among the specifications drawn up by major engineering companies. Field experience shows that DIFLEX gaskets can be used for continuous service at a temperature range of -150°C to +260°C and also under high pressure.

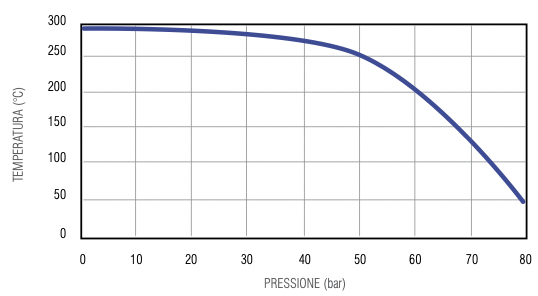

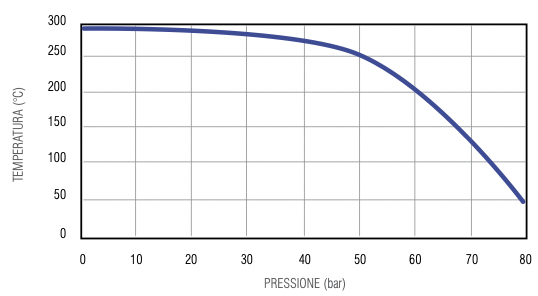

Recommended pxt curve under operating conditions

Gasket life curve (experimental figures)

Versatility of Use

Thanks to their elastic properties, DIFLEX gaskets are suitable for various types of flanges, for example: pipes and fittings made of iron, AISI, iron/PTFE, iron/ENAMEL, CAST IRON, CAST IRON/EBONITE, PVC, MOPLEN, etc.

Practical Remarks

It is very simple to assemble and remove DIFLEX gaskets; DIFLEX gaskets have high shape stability, they are not brittle and they are resistant to shock. After their installation, they perfectly adhere to all surfaces, including uneven ones.

Delivery Conditions

Delivery Conditions

Delivery conditions

PRODUCT COLOUR: Grey or white printed “Diflex - Diflon - Milano”

SHEET SIZE: 1500 x 1500 mm - 1500 x 3000 mm

THICKNESS: 0.5 - 1 - 1.5 - 2 - 3 mm (tolerance: ±10%).

Applications

Acids, Strong alkali, Solvents, Catalyzers, Aromatics, Liquid oxygen, Chlorine, Vapour, etc. Food, Pharmaceutical, Chemical, Petrochemical, Cryogenic industries, etc.

• Operating temperature: -150° + 260° C

• Working pressure at room temperature: 80 bar

• PxT: 12.000 (bar x C°) - pH: 0 ÷ 14

Notes: For lower temperatures, please contact our technical office.

Special Versions

Special Versions

Special Versions

Diflex gaskets are also available in welded versions, even for diameters exceeding 3 m, or according to the customer’s specifications (see page 6). Packaging: packaging poses no problems as the gasket can be folded without the risk of breaking it. Directly available from the warehouse in the standard dimensions shown on page 5.

Diflex Properties

| Properties |

Test Method |

Measure Unit |

Values |

| Density |

ASTM D1457 |

g/cm3 |

2,24 |

Permeability

1 |

- spessore 2 mm - spessore 3 mm |

DIN 3535 at 40 bar DIN 3535 at 40 bar |

cm3/min. cm3/min. |

0,003 0,004 |

| Strain |

ASTM D 621 |

% |

6,5 |

| Tensile strength |

ASTM F 152 ASTM F 152 |

Mpa % |

>12 450 |

| Creep relaxation |

- spessore 2 mm - spessore 3 mm |

ASTM F 38B ASTM F 38B |

% % |

52 68 |

| Compressibility |

ASTM F 36 |

% |

16,7 |

| Springback |

ASTM F 36 |

% |

40÷50 |

| Heat conductivity factor |

DIN 52612 |

W/M.K. |

0,40 |

| |

|

|

| Sealing coeff. m |

- thickness 2 mm - thickness 3 mm |

ASTM F 586/89 ASTM F 586/89 |

-

- |

2,75 2,00 |

| Spec. pressure y |

- thickness 2 mm - thickness 3 mm |

ASTM F 586/89 ASTM F 586/89 |

N/mm2 N/mm2 |

25,5 11,02 |

| Compressive strength 2 |

60 N/mm2 at 23°C |

% |

21 |

Compressive strength

3 |

30 N/mm2 at 150°C |

% |

32 |

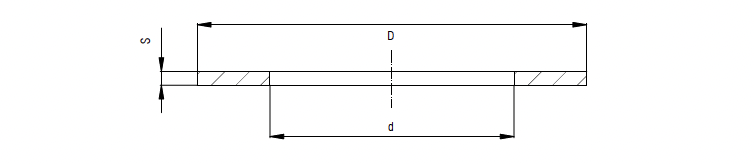

Flat Ring Gaskets Dimensions for raised faces flanges

| |

Raised face flanges - GR - UNI - DIN |

Raised face flanges ANSI B16.5 - RF |

Inches |

| PN 2, 5/6 |

PN 10 |

PN 16 |

PN 25 |

PN 40 |

S. 150 |

S. 300 |

S. 600 |

| |

d |

D |

d |

D |

d |

D |

d |

D |

d |

D |

d |

D |

d |

D |

d |

D |

|

| 10 |

14 |

39 |

14 |

46 |

14 |

46 |

14 |

46 |

14 |

46 |

- |

- |

- |

- |

- |

- |

|

| 15 |

21 |

44 |

21 |

51 |

21 |

51 |

21 |

51 |

21 |

51 |

21,4 |

47,5 |

21,4 |

54,0 |

21,4 |

54,0 |

1/2 |

| 20 |

27 |

54 |

27 |

61 |

27 |

61 |

27 |

61 |

27 |

61 |

27,0 |

57,2 |

27,0 |

66,7 |

27,0 |

66,7 |

3/4 |

| 25 |

33 |

64 |

33 |

71 |

33 |

71 |

33 |

71 |

33 |

71 |

33,3 |

66,7 |

33,3 |

73,0 |

33,3 |

73,0 |

1 |

| 32 |

42 |

76 |

42 |

82 |

42 |

82 |

42 |

82 |

42 |

82 |

42,0 |

76,2 |

42,0 |

82,5 |

42,0 |

82,5 |

1 1/4 |

| 40 |

48 |

86 |

48 |

92 |

48 |

92 |

48 |

92 |

48 |

92 |

48,4 |

85,7 |

48,4 |

95,2 |

48,4 |

95,2 |

1 1/2 |

| 50 |

56 |

96 |

56 |

107 |

56 |

107 |

56 |

107 |

56 |

107 |

60,3 |

104,8 |

60,3 |

111,1 |

60,3 |

111,1 |

2 |

| 65 |

73 |

116 |

73 |

127 |

73 |

127 |

73 |

127 |

73 |

127 |

73,0 |

123,8 |

73,0 |

130,2 |

73,0 |

130,2 |

2 1/2 |

| 80 |

89 |

132 |

89 |

142 |

89 |

142 |

89 |

142 |

89 |

142 |

88,9 |

136,5 |

88,9 |

149,2 |

88,9 |

149,2 |

3 |

| 100 |

114 |

152 |

114 |

162 |

114 |

162 |

114 |

168 |

114 |

168 |

114,3 |

174,6 |

114,3 |

181,0 |

114,3 |

193,7 |

4 |

| 125 |

141 |

182 |

141 |

192 |

141 |

192 |

141 |

195 |

141 |

195 |

141,3 |

196,8 |

141,3 |

215,9 |

141,3 |

241,3 |

5 |

| 150 |

168 |

207 |

168 |

218 |

168 |

218 |

168 |

225 |

168 |

225 |

168,3 |

222,2 |

168,3 |

250,8 |

168,3 |

266,7 |

6 |

| 200 |

219 |

262 |

219 |

273 |

219 |

273 |

219 |

285 |

219 |

290 |

219,1 |

279,4 |

219,1 |

308,0 |

219,1 |

320,7 |

8 |

| 250 |

273 |

317 |

273 |

328 |

273 |

330 |

273 |

340 |

273 |

352 |

273,0 |

339,7 |

273,0 |

362,0 |

273,0 |

400,0 |

10 |

| 300 |

324 |

373 |

324 |

378 |

324 |

385 |

324 |

400 |

324 |

417 |

323,8 |

409,6 |

323,8 |

422,3 |

323,8 |

457,2 |

12 |

| 350 |

356 |

423 |

356 |

438 |

356 |

445 |

356 |

457 |

356 |

474 |

355,6 |

450,9 |

355,6 |

485,8 |

355,6 |

492,1 |

14 |

| 400 |

406 |

473 |

406 |

490 |

406 |

495 |

406 |

514 |

406 |

546 |

406,4 |

514,4 |

406,4 |

539,7 |

406,4 |

565,1 |

16 |

| 450 |

457 |

528 |

457 |

540 |

457 |

555 |

457 |

564 |

457 |

571 |

457,2 |

549,3 |

457,2 |

596,9 |

457,2 |

612,8 |

18 |

| 500 |

508 |

578 |

508 |

595 |

508 |

617 |

508 |

624 |

508 |

628 |

508,0 |

606,4 |

508,0 |

654,0 |

508,0 |

682,6 |

20 |

| 600 |

610 |

680 |

610 |

695 |

610 |

734 |

610 |

731 |

610 |

747 |

609,5 |

717,5 |

609,5 |

774,7 |

609,5 |

790,6 |

24 |

| 700 |

711 |

785 |

711 |

810 |

711 |

804 |

711 |

833 |

711 |

852 |

711,0 |

831,0 |

749,0 |

898,0 |

721,0 |

914,0 |

28 |

| 800 |

813 |

890 |

813 |

917 |

813 |

911 |

813 |

942 |

813 |

974 |

813,0 |

939,0 |

857,0 |

1006,0 |

826,0 |

1022,0 |

32 |

| 900 |

914 |

990 |

914 |

1017 |

914 |

1011 |

914 |

1042 |

914 |

1084 |

914,0 |

1047,0 |

956,0 |

1118,0 |

921,0 |

1130,0 |

36 |

| 1000 |

1016 |

1090 |

1016 |

1124 |

1016 |

1128 |

1016 |

1154 |

1016 |

1194 |

1015,0 |

1162,0 |

1015,0 |

1115,0 |

1005,0 |

1155,0 |

40 |

Flat Ring Gaskets Dimensions

| |

Flange ad incam. semplice |

Flange ad incam. doppia |

pollici |

| UNI/DIN |

ANSI B16.5 |

UNI/DIN |

ANSI B16.5 |

| IS |

LMF |

SMF |

ID |

LTG |

| PN≤6 |

PN≤10 |

300÷2500 |

PN≤6 |

PN≤10 |

300÷2500 |

| |

d |

D |

d |

D |

d |

D |

d |

D |

d |

D |

d |

D |

d |

D |

|

| 10 |

14 |

30 |

14 |

34 |

- |

- |

- |

- |

22 |

30 |

24 |

34 |

- |

- |

|

| |

|

|

|

|

|

|

according to the pipe diameter |

|

|

35 |

29 |

39 |

25,4 |

34,9 |

1/2 |

| 20 |

27 |

42 |

27 |

50 |

27,0 |

42,9 |

23,8 |

32 |

42 |

36 |

50 |

33,3 |

42,9 |

3/4 |

| 25 |

33 |

49 |

33 |

57 |

33,3 |

50,8 |

30,2 |

39 |

49 |

43 |

57 |

38,1 |

50,8 |

1 |

| 32 |

42 |

61 |

42 |

65 |

42,0 |

63,5 |

38,1 |

49 |

61 |

51 |

65 |

47,5 |

63,5 |

1 1/4 |

| 40 |

48 |

68 |

48 |

75 |

48,4 |

73,0 |

44,4 |

56 |

68 |

61 |

75 |

54,0 |

73,0 |

1 1/2 |

| 50 |

56 |

81 |

56 |

87 |

60,3 |

92,0 |

57,1 |

69 |

81 |

73 |

87 |

73,0 |

92,0 |

2 |

| 65 |

73 |

101 |

73 |

109 |

73,0 |

104,8 |

68,3 |

89 |

101 |

95 |

109 |

85,7 |

104,8 |

2 1/2 |

| 80 |

89 |

117 |

89 |

120 |

88,9 |

127,0 |

84,1 |

103 |

117 |

106 |

120 |

107,9 |

127,0 |

3 |

| 100 |

114 |

137 |

114 |

149 |

114,3 |

157,2 |

109,5 |

123 |

137 |

129 |

149 |

131,8 |

157,2 |

4 |

| 125 |

141 |

165 |

141 |

175 |

141,3 |

185,7 |

136,5 |

149 |

165 |

155 |

175 |

160,3 |

185,7 |

5 |

| 150 |

168 |

192 |

168 |

203 |

168,3 |

215,9 |

161,9 |

176 |

192 |

183 |

203 |

190,5 |

215,9 |

6 |

| 200 |

219 |

249 |

219 |

259 |

219,1 |

269,9 |

212,7 |

231 |

249 |

239 |

259 |

238,1 |

269,9 |

8 |

| 250 |

273 |

304 |

273 |

312 |

273,0 |

323,8 |

266,7 |

286 |

304 |

292 |

312 |

285,7 |

323,8 |

10 |

| 300 |

324 |

354 |

324 |

363 |

323,8 |

381,0 |

317,5 |

336 |

354 |

343 |

363 |

342,9 |

381,0 |

12 |

| 350 |

356 |

401 |

356 |

421 |

355,6 |

412,7 |

349,2 |

381 |

401 |

395 |

421 |

374,6 |

412,7 |

14 |

| 400 |

406 |

451 |

406 |

473 |

406,4 |

469,9 |

400,0 |

431 |

451 |

447 |

473 |

425,4 |

469,9 |

16 |

| 450 |

457 |

505 |

457 |

523 |

457,2 |

533,4 |

450,8 |

481 |

505 |

497 |

523 |

488,9 |

533,4 |

18 |

| 500 |

508 |

555 |

508 |

575 |

508,0 |

584,2 |

501,6 |

531 |

555 |

549 |

575 |

533,4 |

584,2 |

20 |

| 600 |

610 |

655 |

610 |

675 |

609,5 |

692,1 |

603,2 |

631 |

655 |

649 |

675 |

641,3 |

692,1 |

24 |

| 700 |

711 |

760 |

711 |

777 |

|

|

|

736 |

760 |

751 |

777 |

|

|

28 |

| 800 |

813 |

865 |

813 |

882 |

|

|

|

841 |

865 |

856 |

882 |

|

|

32 |

| 900 |

914 |

965 |

914 |

987 |

|

|

|

|

941 |

965 |

961 |

987 |

|

|

36 |

| 1000 |

1016 |

1062 |

1016 |

1091 |

|

|

|

|

1036 |

1062 |

1061 |

1091 |

|

|

40 |

Flat Gaskets that are normally used for equipment